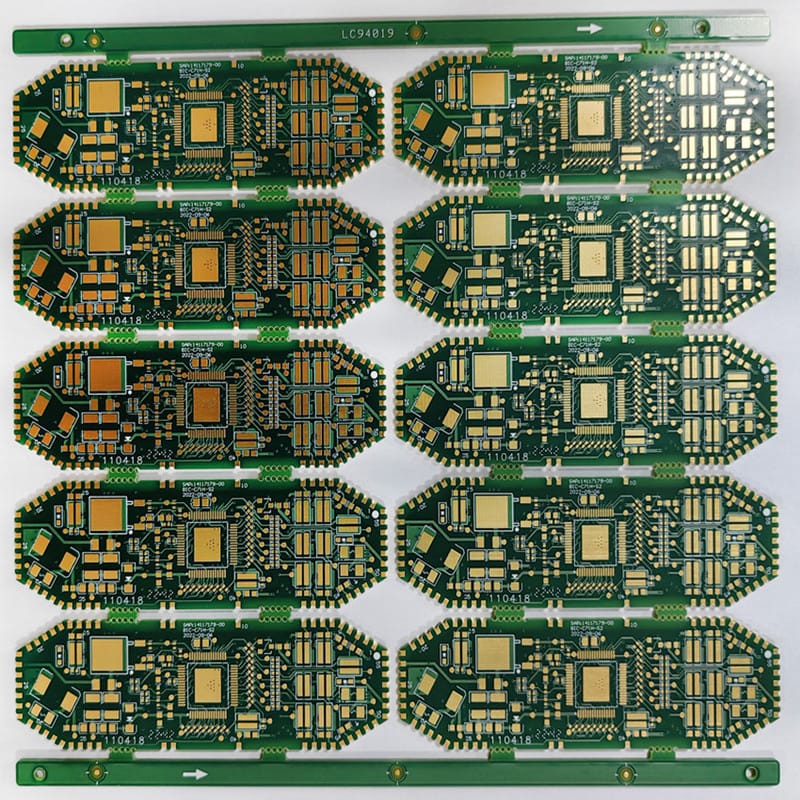

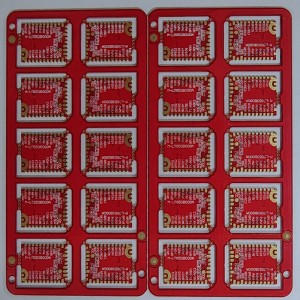

Pcb pawg thawj coj ib nrab qhov ENIG nto TG150

Khoom Specification:

| Khoom siv hauv paus: | FR4 TSI 150 |

| PCB Thickness: | 1.6 +/- 10% mm |

| Txheej suav: | 4L |

| Copper Thickness: | 1/1/1/1 oz |

| Kev kho deg: | ENIG 2U" |

| Solder Mask: | Glossy ntsuab |

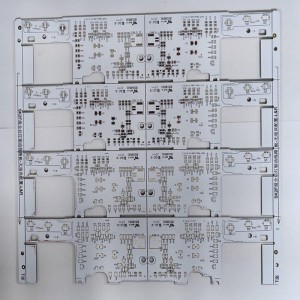

| Silkscreen: | Dawb |

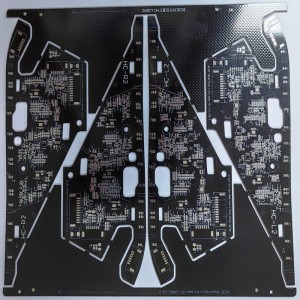

| Cov txheej txheem tshwj xeeb: | Pth ib nrab qhov ntawm ntug |

Daim ntawv thov

Tus nqi TG yog hais txog lub iav hloov pauv kub (Tg), uas yog ib qho tseem ceeb rau qhov thermal stability thiab kub tsis kam ntawm PCB boards.PCB boards nrog TG qhov sib txawv muaj cov khoom sib txawv thiab daim ntawv thov scenarios.Nov yog qee qhov sib txawv:

1. Qhov siab dua tus nqi Tg, qhov zoo dua qhov kub siab ntawm lub rooj tsavxwm PCB, uas yog tsim rau cov ntawv thov scenarios nyob rau hauv qhov kub thiab txias ib puag ncig, xws li automotive electronics, industrial tswj thiab lwm yam kev lag luam.

2. Qhov siab dua Tg tus nqi, qhov zoo ntawm cov khoom siv ntawm PCB pawg thawj coj saib, thiab cov ntsuas lub zog xws li dabtsi yog khoov, tensile, thiab shearing yog zoo dua li cov PCB board nrog tus nqi qis Tg.Nws yog qhov tsim nyog rau cov cuab yeej precision thiab cov khoom siv uas xav tau kev ruaj ntseg siab.

3. Tus nqi ntawm PCB boards nrog tus nqi qis Tg yog qhov qis dua, uas yog qhov tsim nyog rau qee qhov kev thov nrog cov kev xav tau qis dua thiab kev tswj cov nqi nruj dua, xws li cov khoom siv hluav taws xob.Hauv luv luv, xaiv lub rooj tsav xwm PCB haum rau koj tus kheej daim ntawv thov scenario yuav pab txhim kho cov khoom zoo thiab ruaj khov thiab txo cov nqi tsim khoom.

4. Lub tg150 luam ntawv Circuit Court board implies ib tug Circuit Court board tsim nrog ib tug tg150 board.TG feem ntau hais txog qhov hloov pauv ntawm iav, uas yog hais txog qhov hloov pauv tsis tu ncua ntawm cov khoom siv amorphous los ntawm lub xeev khov kho thiab "iav" mus rau lub xeev rubbery thiab viscous thaum siv qhov kub siab tshaj qhov xav tau.Thaum TG feem ntau ua pov thawj qis dua qhov kub ntawm cov khoom siv crystalline sib xws.

5. Cov khoom siv kub hloov pauv iav feem ntau tuaj raws li cov khoom siv kub hnyiab, distorting / melting ntawm qhov kub thiab txias.Lub tg150 PCB los ua cov khoom nruab nrab TG vim nws ntog saum toj ntawm 130 degrees Celsius mus rau 140 degrees Celsius tsis tau qis dua 170 degree Celsius sib npaug lossis siab dua.Thov nco ntsoov tias qhov siab dua TG ntawm lub substrate (feem ntau epoxy), qhov siab dua qhov ruaj khov ntawm cov ntawv luam tawm Circuit Board.

FAQs

Cov cua sov uas yuav tsum tau ua rau PREPREG rigidity yuav tsum tau thov yam tsis muaj tshaj FR4 Tg kom khaws cov PCB ruaj khov.Tus qauv FR4 Tg yog nruab nrab ntawm 130 - 140 ° C, qhov nruab nrab Tg yog 150 ° C thiab qhov siab Tg siab tshaj 170 ° C

Standard Tg nyob saum 130 ℃ thaum siab Tg siab tshaj 170 ℃ thiab nruab nrab Tg siab tshaj 150 ℃.Thaum nws los txog rau cov khoom siv rau PCBs, siab Tg yuav tsum tau khaws, uas yuav tsum siab tshaj qhov ua haujlwm kub tam sim no.

Lub tg150 PCB los ua cov khoom nruab nrab TG vim nws ntog saum toj ntawm 130 degrees Celsius mus rau 140 degrees Celsius tsis tau qis dua 170 degree Celsius sib npaug lossis siab dua.Thov nco ntsoov tias qhov siab dua TG ntawm lub substrate (feem ntau epoxy), qhov siab dua qhov ruaj khov ntawm cov ntawv luam tawm Circuit Board.

Qhov tseem ceeb tshaj plaws los txiav txim siab seb puas siv 150 lossis 170 Tg cov khoom siv PCB yog qhov ua haujlwm kub.Yog tias nws tsawg dua 130C / 140C, ces Tg 150 cov khoom siv tau zoo rau koj lub PCB;Tab sis yog tias ua haujlwm kub nyob ib puag ncig 150C, ces koj yuav tsum xaiv 170 Tg.

Lub siab Tg PCB muaj cov txheej txheem resin uas tau tsim los tiv thaiv cov hlau lead-dawb soldering thiab ua kom muaj zog dua txhua yam hauv qhov hnyav, qhov kub thiab txias.Resin yog hais txog cov khoom siv los yog semisolid organic uas feem ntau siv hauv cov yas, kua roj vanish, thiab lwm yam.