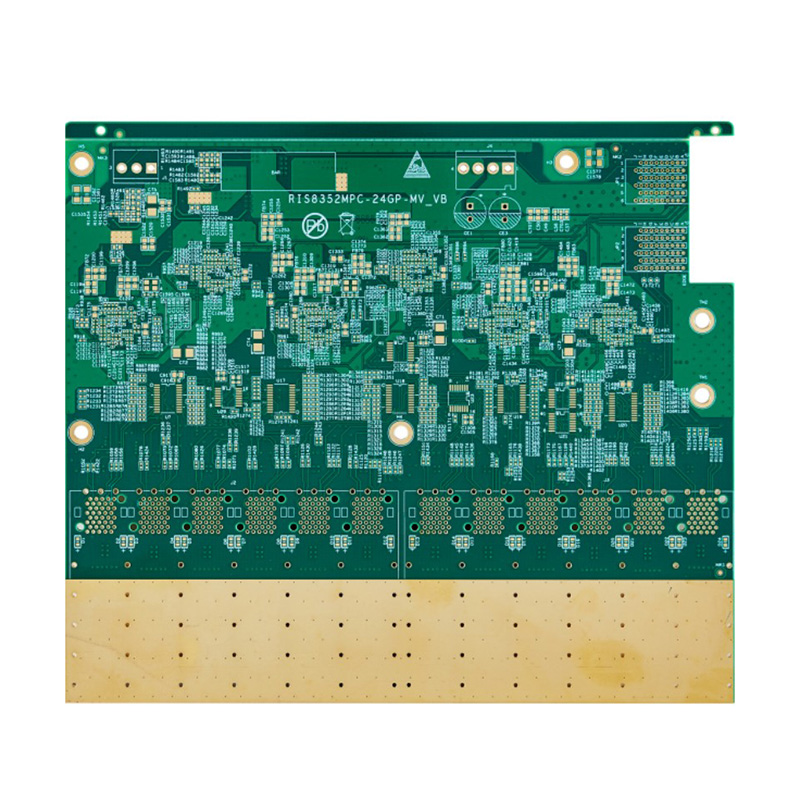

Kev cai 10-txheej HDI PCB nrog hnyav kub

Khoom Specification:

| Khoom siv hauv paus: | FR4 TSI 150 |

| PCB Thickness: | 2.0 +/- 10% mm |

| Txheej suav: | 10 L |

| Copper Thickness: | Sab nraud 1oz & puab 0.5oz |

| Kev kho deg: | Plated Kub |

| Solder Mask: | Ntsuab |

| Silkscreen: | Dawb |

| Txheej txheem tshwj xeeb: | Hnyav kub |

Daim ntawv thov

HDI PCB feem ntau pom muaj nyob rau hauv cov khoom siv hluav taws xob nyuaj uas xav tau kev ua haujlwm zoo thaum txuag chaw. Cov ntawv thov suav nrog cov xov tooj ntawm tes / xov tooj, cov khoom siv kov npo, khoos phis tawj khoos phis tawj, lub koob yees duab digital, 4/5G network kev sib txuas lus, thiab kev siv tub rog xws li avionics thiab riam phom ntse.

FAQs

HDI sawv cev rau High Density Interconnector. Ib lub rooj tsav xwm hauv Circuit Court uas muaj qhov sib txuas ntau dua ntawm ib cheeb tsam uas tsis yog lub rooj tsav xwm pom zoo hu ua HDI PCB. HDI PCBs muaj qhov chaw zoo dua thiab cov kab, me me vias thiab ntes cov ncoo thiab ntau dua kev sib txuas ncoo ceev. Nws muaj txiaj ntsig zoo hauv kev txhim kho hluav taws xob ua haujlwm thiab txo qhov hnyav thiab qhov loj ntawm cov khoom siv.HDI PCByog qhov kev xaiv zoo dua rau cov txheej txheem siab suav thiab kim laminated boards.

HDI PCBs muab kev tiv thaiv ntau dua ntawm cov ntawv me me, sib dua uas feem ntau muaj cov txheej txheem tsawg dua rau lawv thaum piv nrog cov PCBs.. HDI PCBs siv laser drilling, micro vias, thiab muaj qhov sib piv qis dua ntawm cov vias dua li cov qauv Circuit Court boards.

Lawv yog cov kev daws teeb meem zoo txhua lub sijhawm uas koj yuav tsum tau txo qhov loj thiab qhov hnyav, thiab thaum koj tseem yuav tsum muaj kev ua haujlwm thiab kev ntseeg siab hauv cov khoom. Ib qho ntawm lwm cov txiaj ntsig tau pom nrog cov laug cam no yog qhov tseeb tias lawv siv cov thev naus laus zis hauv-hauv-pad thiab qhov muag tsis pom ntawm cov thev naus laus zis.Qhov no tso cai rau cov khoom sib xyaw ua ke los ze zog ua ke, txo qhov ntev ntawm cov teeb liab txoj kev, uas yuav pab tau sai thiab ntau dua. cov teeb liab txhim khu kev qha txij li cov kev no luv dua.

Nws nyob ntawm qhov nyuaj ntawm koj cov ntaub ntawv gerber, nws yog qhov zoo dua los xa nws mus rau peb tus engineer rau kev ntsuam xyuas ua ntej.

1. E-Test

2. AOI – Test (Kev kuaj xyuas qhov muag tsis pom)

3.X-ray(xyuas qhov tseeb ntawm kev sau npe rau multilayers)

4. CCD –Lub koob yees duabTswj Drilling. Kev pov thawj ntawm kev tsim khoom kam rau ua

5. Impedance tswj

HDI PCBs siv nyob qhov twg niaj hnub no?

Vim tias cov txiaj ntsig lawv muab, koj yuav pom tias HDI PCBs tau siv ntau yam khoom siv hluav taws xob thoob plaws ntau qhov kev lag luam sib txawv. Kev lag luam kho mob yog ib qho ntawm cov neeg paub zoo tshaj plaws. Cov cuab yeej kho mob uas tau ua niaj hnub no feem ntau yuav tsum me me. Txawm hais tias nws yog ib qho khoom siv hauv chav kuaj lossis cov khoom cog, me me yuav yog qhov kev xaiv zoo dua, thiab HDI PCBs tuaj yeem pab tau ntau yam hauv qhov no. Pacemakers yog ib qho piv txwv zoo ntawm ib hom khoom uas siv cov PCBs no. Ntau hom kev soj ntsuam thiab tshawb xyuas cov cuab yeej, xws li endoscopes lossis colonoscopes, siv hom tshuab no. Ib zaug ntxiv, me dua yog qhov zoo dua hauv cov xwm txheej no.

Ntxiv rau thaj chaw kho mob, kev lag luam tsheb tau siv HDI PCBs. Txhawm rau pab txhawb qhov chaw muaj nyob hauv cov tsheb loj, lawv tau ua qee yam khoom siv hluav taws xob me me. Tau kawg, ntsiav tshuaj thiab smartphones siv hom tshuab no. Qhov no yog vim li cas thiaj li muaj ntau yam ntawm cov cuab yeej no ua sib zog thiab nyias dua los ntawm lawv cov tiam.

Koj tseem yuav pom HDI PCBs siv nyob rau hauv aerospace thiab tub rog teb. Lawv kev ntseeg tau thiab lawv qhov me me ua rau lawv muaj txiaj ntsig rau ntau yam kev siv sib txawv. Nws zoo li yuav muaj ntau thiab ntau cov khoom siv los ntawm ntau lub teb chaws uas yuav siv cov thev naus laus zis no mus tom ntej.